A LIGO Optics Technician applies servo magnets to one of LIGO's fused silica masses. (Credit: Caltech/MIT/LIGO Lab)

LIGO Optics

U.S. National Science Foundation Laser Interferometer Gravitational-wave Observatory (NSF LIGO) primary interferometer optics include exquisite mirrors called "test-masses". The term "test mass" comes from relativity theory, where it is used to describe a mass free from forces and able to follow distortions of space-time. In addition, NSF LIGO's instrument includes laser beam splitters, a power-recycling mirror, and a signal recycling mirror. The mirror technology in LIGO’s detectors represents the accomplishments of a decades-long global collaboration.

Two of LIGO's 'test masses' (mirrors), so called because they 'test' (or feel for) changes in LIGO's arm-lengths caused by a passing gravitational wave. Each silica cylinder weighs 40kg. (Credit: Caltech/MIT/LIGO Lab)

LIGO’s test-masses are made of fused silica, cast from ultra-pure material with low OH (hydroxide) content to minimize infrared (IR) absorption. Since LIGO’s laser is an IR laser, its optics must not absorb IR radiation. Doing so would result in heating and in significant changes to the shape of the mirrors, thus critically affecting LIGO’s ability to make the precise measurements it needs to make. LIGO’s main mirrors only absorb one out of every 3.3 million photons, the rest being reflected (or transmitted). Some heating does occur, but an auxiliary system using a CO2 laser heats the mirrors precisely enough to counteract the shape-changes that occur as a result of heating from LIGO’s main laser.

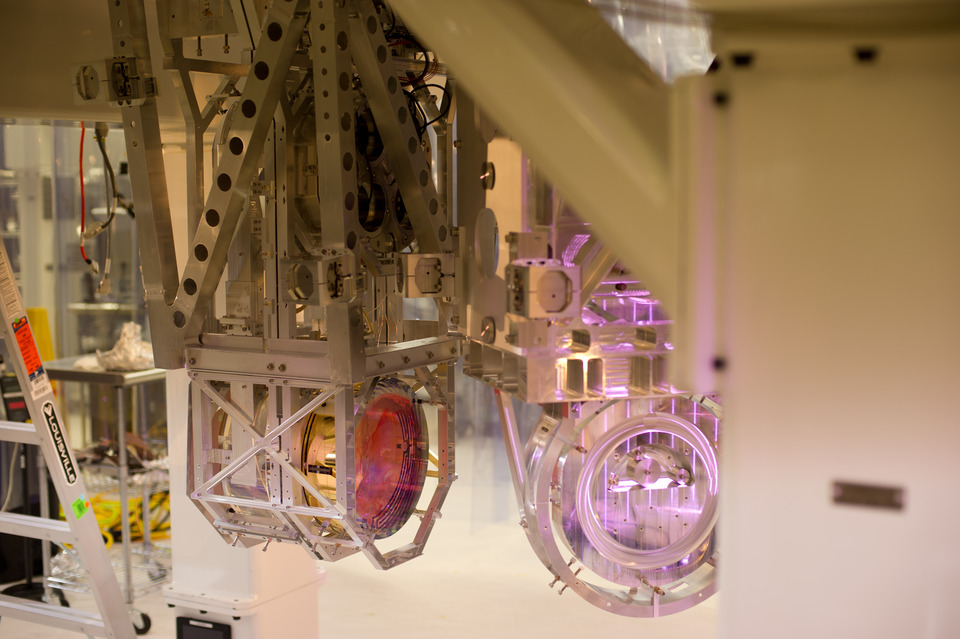

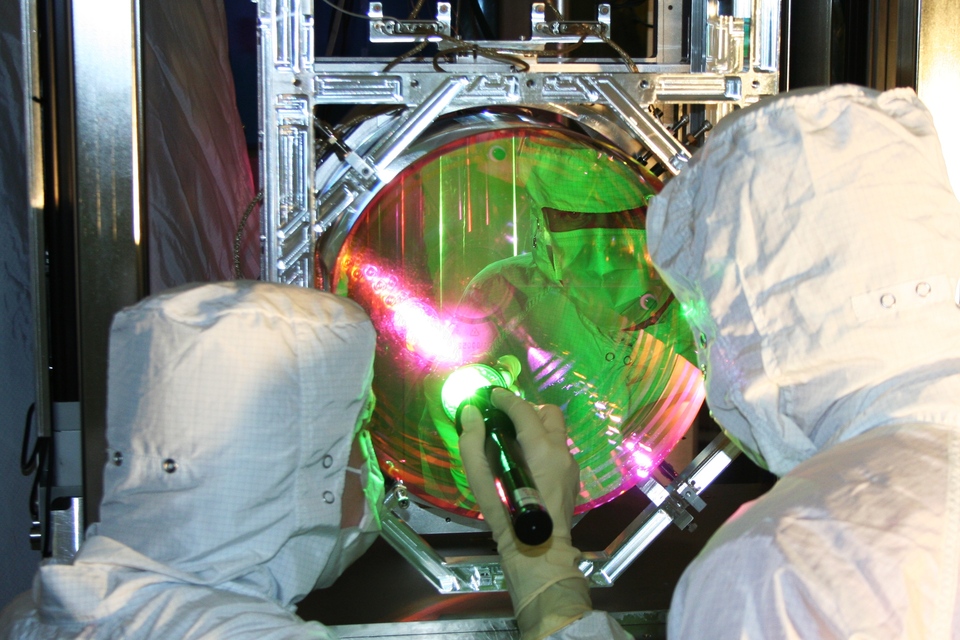

Technicians inspect the "First Contact" coating on one of LIGO's Input Test Masses. (Credit: Caltech/MIT/LIGO Lab)

LIGO’s optics are also hefty. The input and end test-masses each weigh 40kg (88lbs.) giving them large inertial masses that intrinsically provide some level of vibration resistance thanks to the law of Inertia (although much more is required. See Vibration Isolation). The image at right shows two of LIGO's test-masses before they were installed in the interferometer.

The test-masses are coated with dozens of layers of optical coatings and polished to nanometer smoothness, making them incredible mirrors. Again, this level of precision is required to ensure that LIGO’s laser encounters a clean, stable, and perfectly tooled reflective surface enabling it to follow a clean path as it travels through the interferometer, making about 300 reflections before reaching the photodetector. Without these precautions, detecting a gravitational wave would be impossible.